Get advice

Contact VMI in your region

Select your

VMI Office:

VMI Holland BV | Head Office

- Gelriaweg 16

- 8161 RK Epe

- The Netherlands

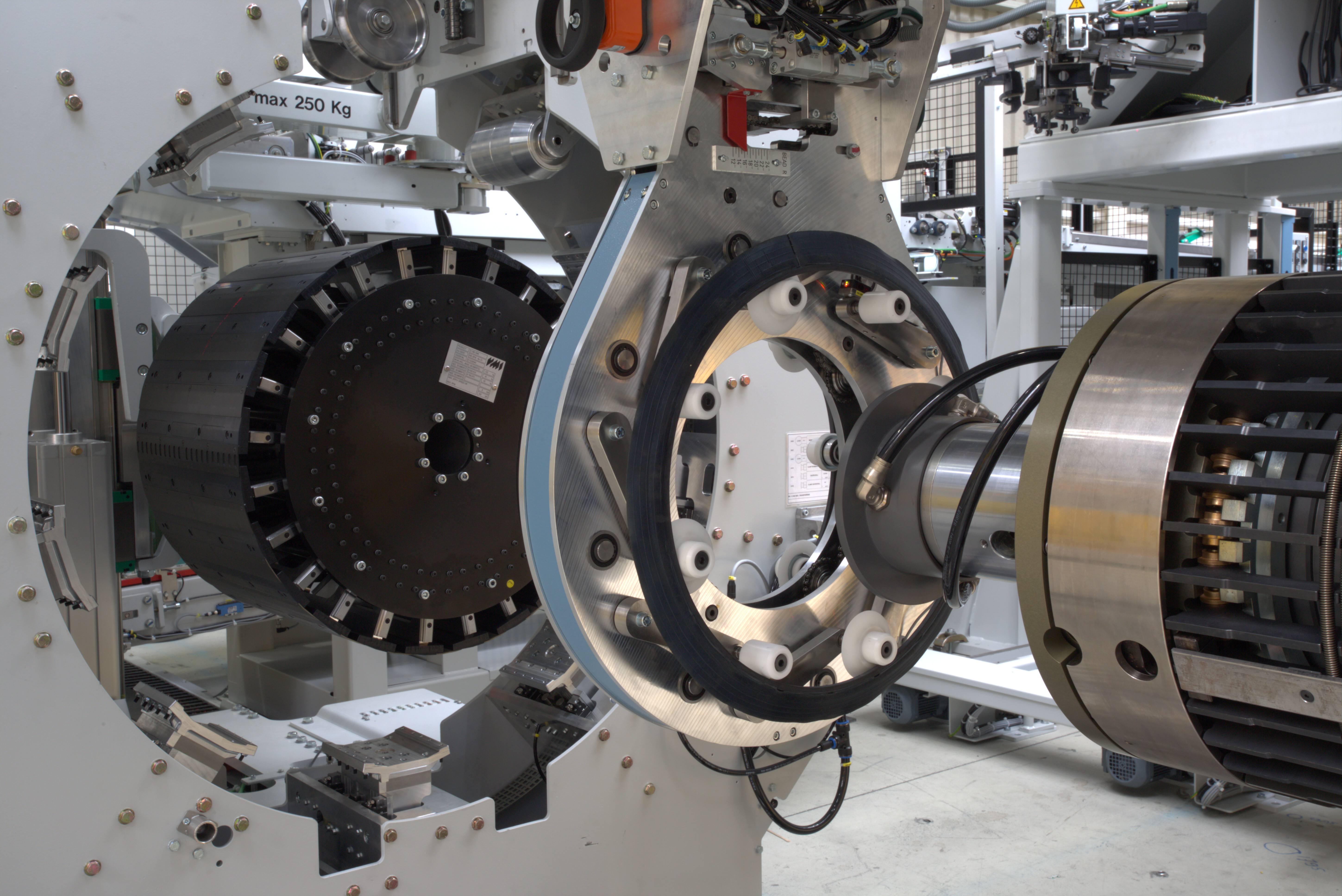

The VMI MAXX radial passenger tire building machine maximizes output, quality, ergonomics and flexibility. At the same time, set-up times, maintenance and machine complexity have been minimized, making it possible for just one person ‘with hands-off eyes-off’ to operate multiple systems. The two-drum machine combines a high level of flexibility with an unrivalled high capacity and excellent green tire quality.

The basic system comprises several modules. The tire assembly machine is the front end of the machine where the tire is assembled in two parallel processes: building the belt & tread package at the belt & tread side and building the carcass package at the carcass side.

The belt & tread side on the left of the machine consists of a belt & tread drum housing which moves along the track and makes vertical movements. This enables the use of fixed belt, tread and cap strip applicators, creating a more consistent process. The drum housing moves the drum to the applicator and, if necessary, makes corrective movements during the application.

The carcass side on the right of the machine consists of a moving carcass drum housing, which moves the carcass drum from the applicator to the transfer ring. The bead setters are split and move independently along the track. The multi disc applicator roll, the brush roll and the Clip-Bar for automatic pre-assembly application are robustly and sturdily mounted to the top frame. The multi disc roll has 16 independent zones. All zones can be driven individually.

The fixed transfer ring is located at the center of the tire assembly machine and is a solid part of the frame. It is the part of the machine where the green tire is finally assembled. Both the green tire removal unit and the offline bead loader are located near the transfer ring, in an area that is accessible for the operator making it also possible to manually load beads and taking a green tire out for inspection. The areas in front of the belt & tread and carcass side are guarded by light curtains.

Contact VMI in your region