- Reduced risk of long downtime

- Improved performance

- Reduced Total Cost of Ownership

- ROI based proposals ready for your business case / budget request

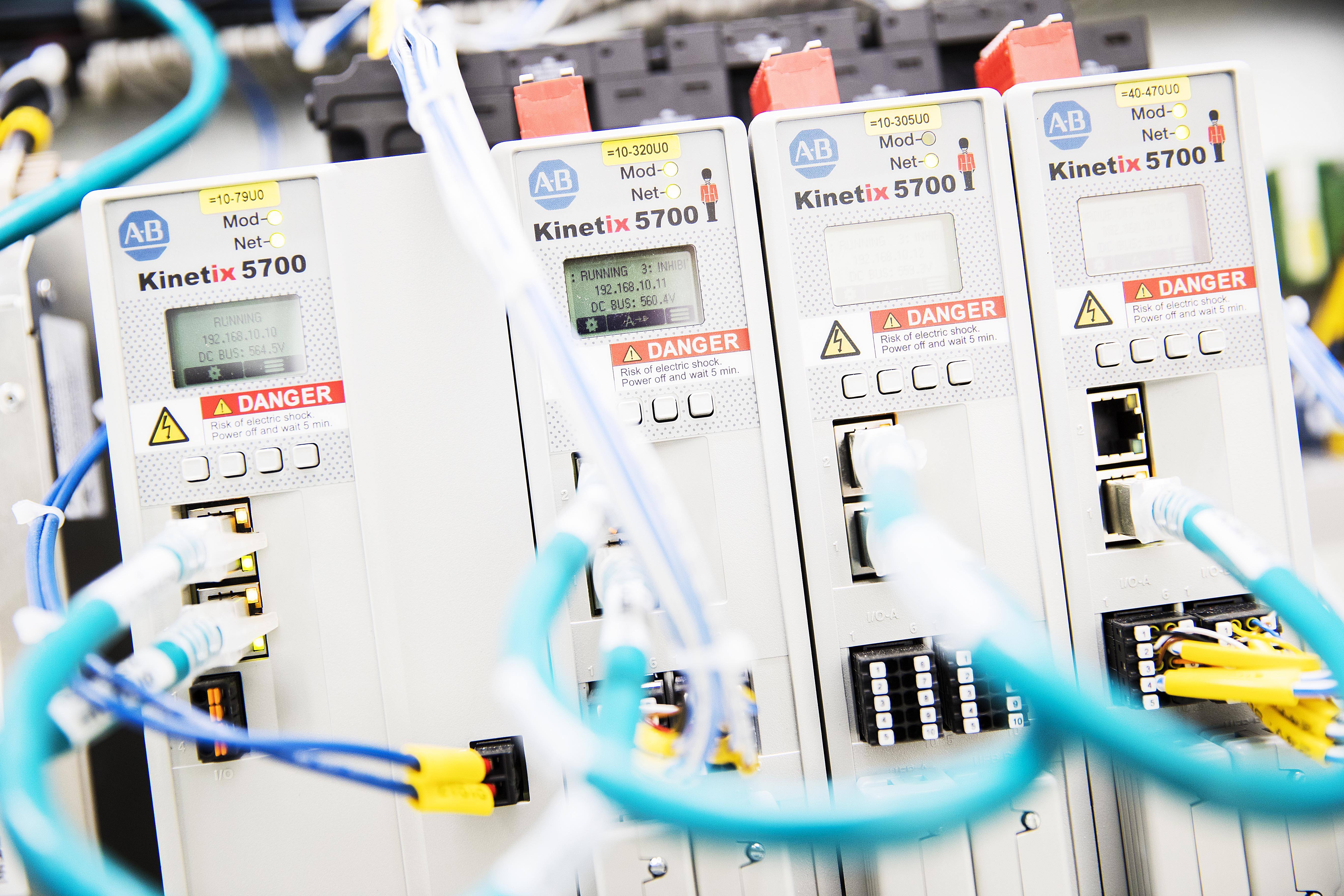

Developments on technical systems are accelerated by the release of new technologies. In today’s digital age, processing speeds and utility consumption amongst others are continuously improved. These improvements lead to new developments in hardware and functionalities that are indispensable if you work with the best high tech equipment in the world. This also means that regular updates and replacement of these obsolete systems or parts are inevitable, if you want to assure that your machine remains in top condition.

With regards to obsolete parts, VMI always strives to find the optimum solution for our machines and customers by negotiating the longest life cycles and support periods possible from our suppliers. We furthermore take great care in designing and selecting components, so that we can obtain the longest life cycle out of these at the lowest costs.

We understand the cost impact of having to replace obsolete systems and therefore jointly with you look for alternatives and when possible phase the replacement of these systems over time. Here we make use of a hybrid situation where a selection of old systems are replaced by new ones, thus allowing the old replaced parts to become spare parts should the other not yet replaced old system fail.

Mitigating risks are an important driver, but new technologies also bring new functionality or improved specifications. Our Service Advisors are available to assist you to evaluate all possibilities for your install base. Based on a positive return on investment calculation, VMI offers you these Upgrades, which you can easily incorporate into your business case.

Your VMI Service Advisor is your single point of contact during the complete process. Possibilities for your machines are evaluated and recommendations prioritized on what should be done urgently to mitigate risks like downtime, or what can be seen as plannable for future long term investment. Part of the discussion is to determine the added value for your organization and to scope the replacement in such a way that it is risk free and affordable.

When the order is placed for an Upgrade, engineering is done and hardware ordered. After production, the Upgrade kit is delivered to your factory and the VMI Field Service team installs it if it is not possible to plug and play the kit by your own maintenance staff. The Upgrade is further completed by training for your Operators and Maintenance teams and you receive updated machine documentation and certifications matching the new configuration.