Get advice

Contact VMI in your region

Select your

VMI Office:

VMI Holland BV | Head Office

- Gelriaweg 16

- 8161 RK Epe

- The Netherlands

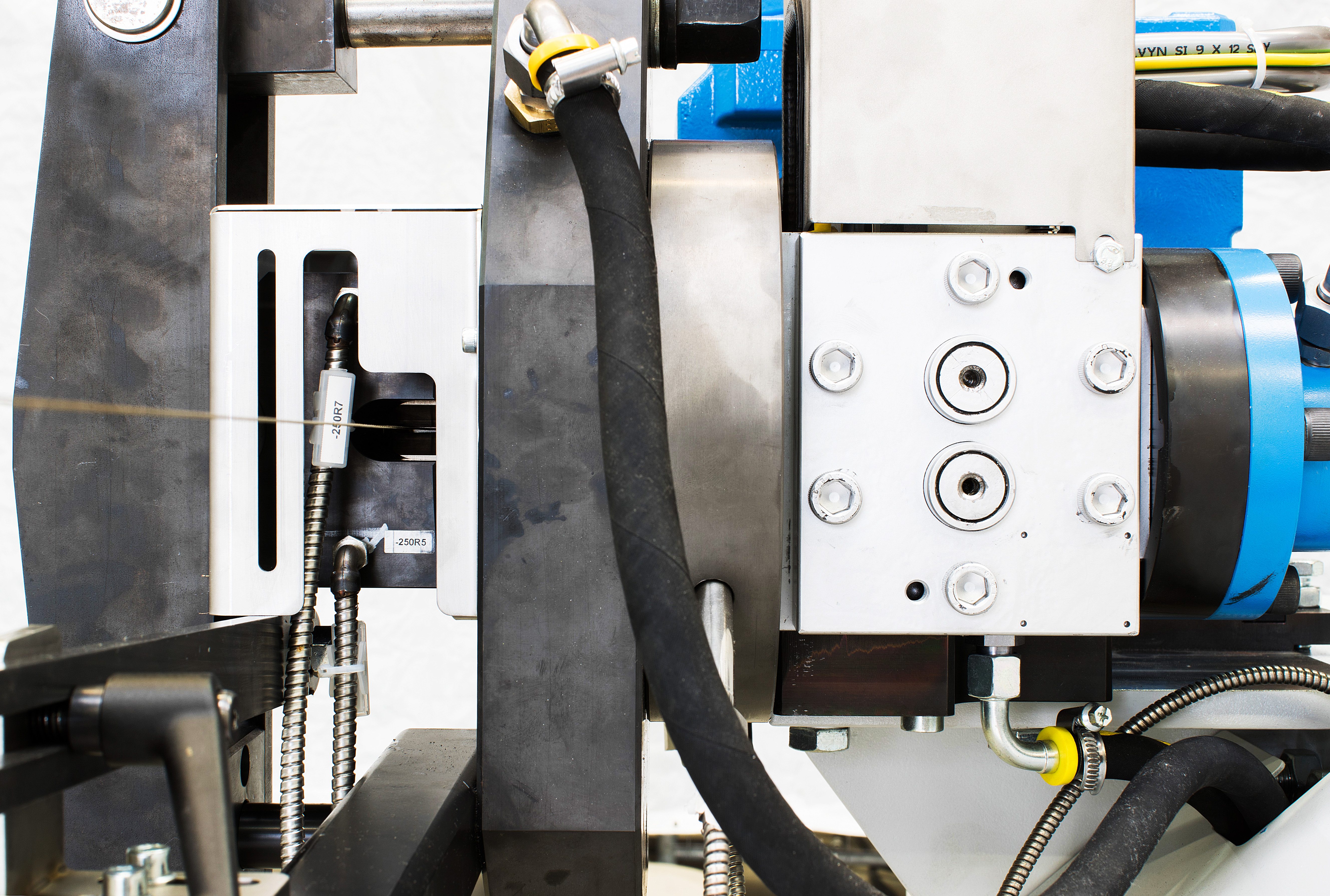

Extrusion strip winding is important for OTR tire retreading and has also become important for new tire production systems, to build up full rubber tire components by winding a small rubber strip delivered by an extrusion system. Such applications require strip extrusion with very high accuracy and high output pressure. Therefore VMI extrusion systems include a gear pump in conjunction with a single screw extruder.

VMI’s dedicated extruder gear pump systems meet the output requirements for this type of application while the customer takes care of further system integration. The linear and predictable output of the gear pump enables easy integration.

The machine process section can feature a swing frame design for the single screw extruder so that the extruder can be quickly and easily pivoted away from the gear pump inlet to allow cleaning of the compound and complete empty run of the extruder screw.

Contact VMI in your region